Environment-friendly mobility is a highly important segment of the automotive industry, and it brings numerous challenges to all of us involved as Tier 1 or strategic partners. These start from the very beginning, when a concept for a new car model with different engines (ICE, hybrid or electrical) is created.

Cimos e-transportation manufacturing division’s core technologies include aluminum high and low pressure die casting, aluminum gravity die casting, hot forging, CNC machining and grey iron casting. The division mainly operates as an engineered products’ service provider from a Tier 1 market position, and acts as both a strategic and preferred supplier, with majority of their supply contracts booking as single source.

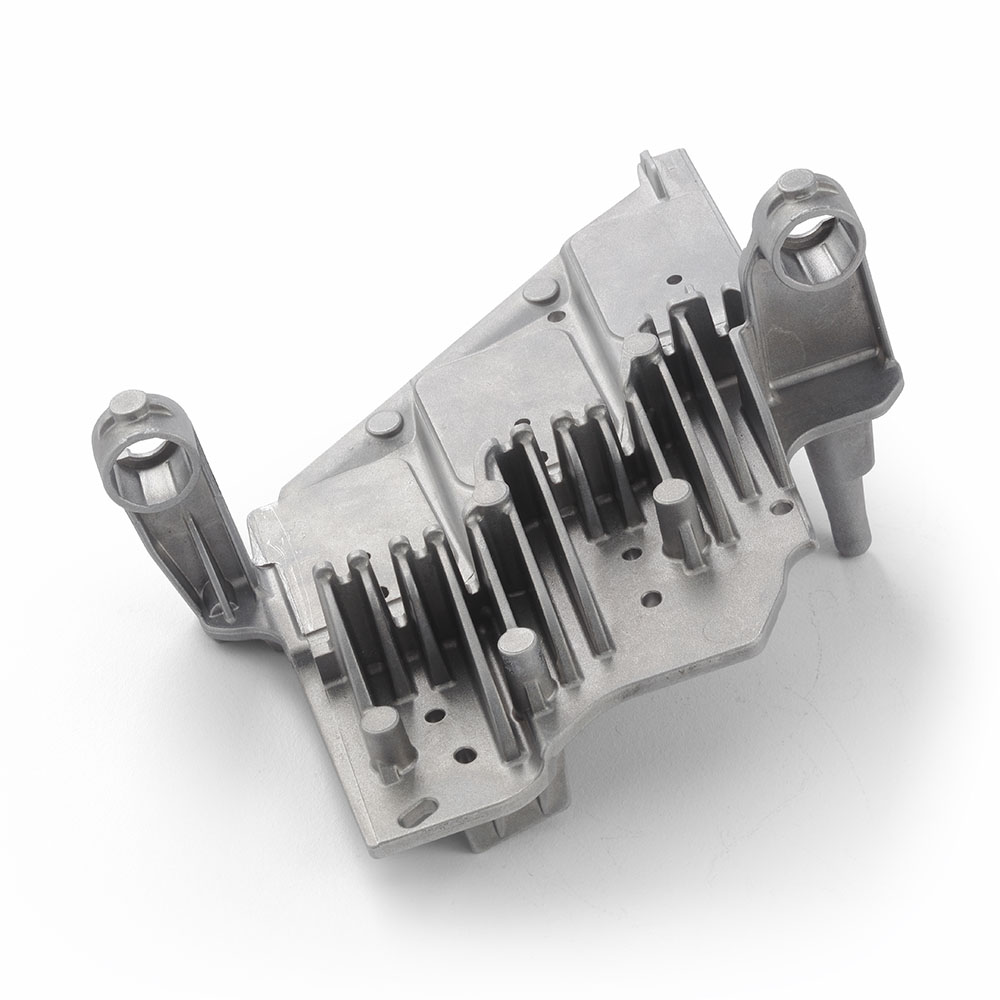

Engine & Accessory brackets

Long-lasting relationships in joint development work with main European OEMs

View all components

Flywheels

A European-leading producer of OEMs with decades of experience in development, design and production of single mass flywheels

View all components

Gearbox parts

Lightweight and highly functional parts with the ability for production to be rapidly implemented

View all components

Other chassis parts

Very competitive in chassis components thanks to our partnership with leading European OEMs

View all components

Other e-transportation parts

Intelligent, cost optimized and lightweight product solution for various applications

View all components

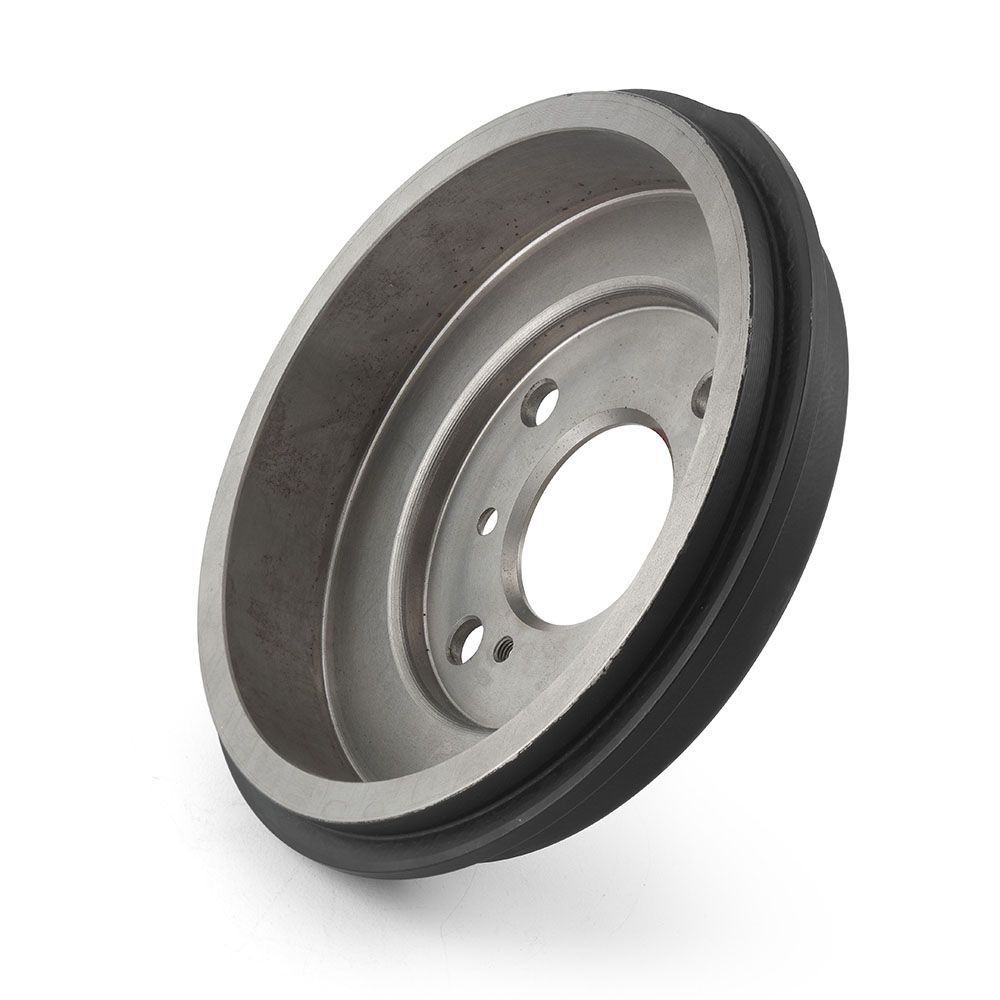

Brake discs and drums

Optimal cost production locations dovetailed with efficient production infrastructure, resulting in competitive pricing

View all componentsList of e-transportation components

Our valued clients

We are an original equipment supplier to nearly every major automotive original equipment manufacturer (OEM) of passenger cars, SUVs, and vans in Europe and to the biggest Tier 1 vehicle systems suppliers.

Manufacturing Capabilities

Cimos works closely with customers to tailor products to specific needs.

01.

Product design & validation

- Development of a product 3D model based on Customer requirements.

- Production of prototypes.

- Physical validations of the prototypes.

02.

Process engineering

- Definition of the production process details: operations, machinery, tooling, parameters, etc.

- Coordination with Customer to ensure effective production.

03.

Manufacturing process

- Melting, Sand core shooting, Casting, Finishing, Machining, Washing & Control, Leak test & Assy.

04.

Delivery

- Final products are delivered to Customers for assembly into their product (Tier 1 OES), engine or vehicle (OEM).

First grade excellence

KPI Excellence

Cimos closely monitors the execution of our company-wide strategy and targets through KPIs, which are in line with automotive standards and comprise all critical dimensions.

Contact us or request a visit

For further information, do not hesitate to contact us. Fill out the form and we will be happy to respond to any of your requests or questions.

Dev note:

slika v ozadju, mobile height

We strive for higher quality

Cimos has cultivated long-standing relationships across its customer base. We have been working with our top 10 customers for the last 10 to 20 years.

Research first, then develop

The company has developed a strong process specialization and competencies on a complex sequence of manufacturing activities.

Dev note:

slika v ozadju, mobile height

Dev note:

slika v ozadju, mobile height

Dev note:

slika v ozadju, mobile height

Dev note:

slika v ozadju, mobile height

High-end tech at your service

Customer trust and consistent product quality made Cimos the supplier of choice, with majority of new projects on a single-source basis.

Next generation

Air compression components

Air compression components drastically reduce fuel consumption and engine emissions.

With innovative solutions both in product development and manufacturing technology, we have become a trusted partner for leading automotive OEMs and Tier 1 suppliers.